Ferrule Fittings

WHAT ARE FERRULE FITTINGS? .

Ferrule fittings connect and seal tubes in a hydraulic or pneumatic system. They provide a strong and leak-proof connection and are crucial in applications with high pressures, vibration, and temperature changes. For a quick comparison, single ferrule fittings are typically used for low-pressure applications, less demanding environments, and they are cheaper than double ferrule fittings. Double ferrule fittings are typically used for high- pressure applications and when superior sealing performance and reusability are required.

What are single and double ferrule fittings?

Compression fittings have three core components: a compression nut, one or two

ferrules, and a body.

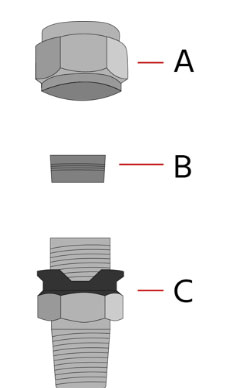

Single ferrule fittings

Single ferrule fittings have one ferrule (Figure 2 labeled B), which provides the sealing pressure against the fitting body (Figure 2 labeled C) and the tube. As the compression nut (Figure 2 labeled A) is tightened, the shoulder inside engages with the ferrule's back end. This results in the angled front end of the ferrule compressing into the body and securely gripping the tube.

Figure 2: Single ferrule tube fitting anatomy: compression nut (A), single ferrule (B), and fitting body (C)

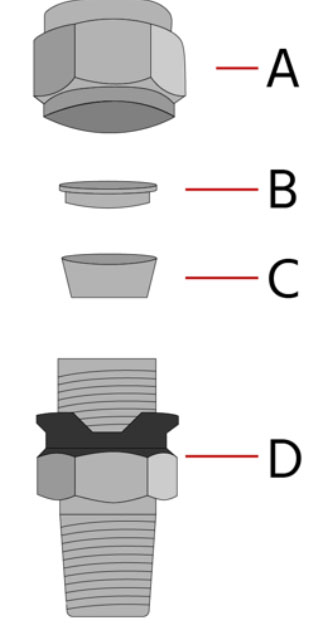

Double ferrule fittings

A double ferrule fitting has two ferrules.

The front ferrule (Figure 3 labeled C) is the larger piece that sits deep in the

body. The back ferrule (Figure 3 labeled B) is small and engages with the

compression nut (Figure 3 labeled A).

The softer, metal front ferrule securely seals the connection by compressing

between the tube and the fitting body (Figure 3 labeled D). On the other hand,

the back ferrule is equipped with a chemically-hardened lead edge, allowing it

to grip the softer metal of the tubing firmly. This gripping action effectively

prevents the tubing from slipping under high pressure, ensuring a safe and

reliable fluid control system.

Figure 3: Double ferrule fitting anatomy: compression nut (A), back ferrule (B), front ferrule (C), and fitting body (D)

| STANDARD | ASTM A276, ASME SA479, ASTM A182, ASME SA182 |

| MATERIAL | STAINLESS STEEL (SS304 & SS316), BRASS, TITANIUM, AND SPECIAL ALLOYS |

| SIZE RANGE | FRACTIONAL TUBE(INCH)-1/16”-1 ½” , METRIC TUBE(MM)-2MM-38MM |

| PRESSURE RATING | 3000psi-10000psi |

| THREADS | NPT, BSPT, BSP |