Forged Fittings

Forged fittings are essential components in various industries, known for their strength and reliability. The process of making forged fittings involves several steps, each critical to ensuring the final product meets high standards. Here's a detailed guide to creating forged fittings.

Forged fittings find applications across various industries including oil and gas, chemical and Petrochemical, Power, Shipbuilding and Marine, Aerospace, Construction and Infrastructure, Automotive, Food and Beverage, Pharmaceutical, Mining and Mineral. Forged fittings are used in piping systems to connect straight pipe or tubing sections, adapt to different sizes or shapes, and for other purposes, such as regulating or measuring fluid flow. They are typically made by forging, which is a manufacturing process involving the shaping of metal using localized compressive forces.

Forged Fittings Specification

| Attribute | Specification |

|---|---|

| Standards Compliance | ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, BS 3799,ASTM A182,ASTM A105,ASME SA105,ASTM A403,ASTM A420 |

| Sizes | 1/2" to 4" |

| Pressure Rating | 2000 psi (2000 #) (Threaded), 3000 psi (3000 #)(Threaded & Socketweld), 6000 psi (6000 #)(Threaded & Socketweld), 9000 psi (9000#) (Socketweld) |

| Connection Types | Socket Weld, Threaded (NPT, BSP, BSPT) |

| Dimensional Tolerances | As per ASME B16.11 specifications |

| Surface Finish | Plain, Galvanized, Nickel Plated, Passivated (for stainless steel) |

| Heat Treatment | Normalized, Quenched and Tempered, Annealed (based on material) |

| Certification | Mill Test Certificate (MTC) as per EN 10204 3.1, 3.2 |

| Corrosion Resistance | Applicable for Stainless Steel, Alloy Steel, Duplex materials |

| Testing | Hydrostatic Test, Magnetic Particle Inspection (MPI), Dye Penetrant Test (DPT), Ultrasonic Testing (UT) |

| Temperature Range | According to class (psi) & Material |

| Marking | Manufacturer’s name, Size, Pressure Class, Material Grade, Heat Number |

| End Preparation | Beveled, Plain, Threaded as per ASME B16.11 |

| Special Features | High-pressure, High-temperature resistance, Customization available |

| Material | Common Grades | Typical Applications |

|---|---|---|

| Carbon Steel | ASTM A105, A350 LF2 | Oil and gas, power generation, chemical processing, plumbing |

| Stainless Steel | 304,304L,310S,316,316L,317L,321,347, 410,410S,420,420F,430,430F,431,440A,440B,440C, 904L |

Chemical and petrochemical, food processing, pharmaceuticals |

| Alloy Steel | ASTM A182 F5, F9, F11, F22 | Oil and gas, power generation, aerospace, automotive |

| Duplex Stainless Steel | ASTM A182 F51 (Duplex), F53 (Super Duplex) | Oil and gas, chemical processing, marine and offshore applications |

| Nickel Alloys | ASTM B564, ASTM B865 | Aerospace, chemical processing, marine environments |

| Titanium | Titanium Grade 1, Titanium Grade 2 , Titanium Grade 3 and Titanium Grade 4, Titanium Grade 5 | Aerospace, marine, chemical processing |

| Copper Alloys | ASTM B61 (Copper Nickel 90/10) (Copper Nickel 70/30), ASTM B62 (Brass) | Marine, plumbing, heat exchangers |

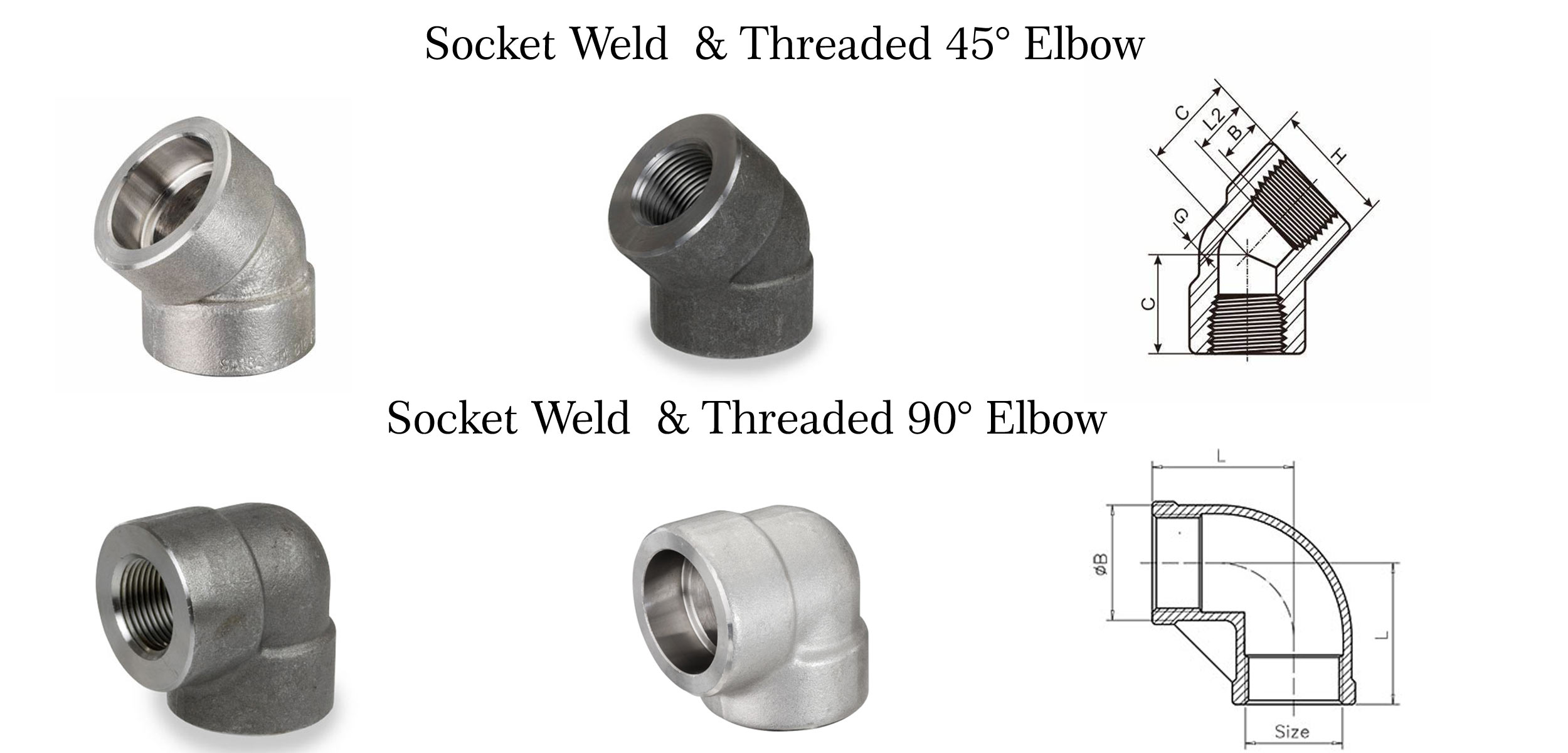

| Nominal Diameter | Depth of Socket | Dimension of Socket | Wall Thickness | Center to Bottom of Socket | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | ||||||||||||

| Cmin | 90°Elbow | 45°Elbow | ||||||||||

| DN | NPS | Jmin | d1 | 3000LB | 6000LB | 9000LB | 3000LB | 6000LB | 9000LB | 3000LB | 6000LB | 9000LB |

| 6 | 1/8 | 10 | 10.7 | 3.2 | 3.5 | - | 11 | 11 | - | 8 | 8 | - |

| 8 | 1/4 | 10 | 14.1 | 3.3 | 4 | - | 11 | 15 | - | 8 | 8 | - |

| 10 | 3/8 | 10 | 17.5 | 3.5 | 4.4 | - | 13 | 15 | - | 8 | 12 | - |

| 15 | 1/2 | 10 | 21.8 | 4.1 | 5.2 | 8.2 | 16 | 19 | 25 | 11 | 13 | 16 |

| 20 | 3/4 | 13 | 27.4 | 4.3 | 6.1 | 8.6 | 19 | 22 | 28 | 13 | 14 | 18 |

| 25 | 1 | 13 | 34.2 | 5 | 7 | 10 | 22 | 27 | 32 | 14 | 18 | 22 |

| 32 | 1.1/4 | 13 | 42.9 | 5.3 | 7 | 10.6 | 27 | 32 | 35 | 18 | 21 | 22 |

| 40 | 1.1/2 | 13 | 48.3 | 5.6 | 7.8 | 11.2 | 32 | 38 | 38 | 21 | 25 | 25 |

| 50 | 2 | 13 | 61.1 | 6.1 | 9.5 | 12.2 | 38 | 41 | 41 | 25 | 29 | 29 |

| 65 | 2.1/2 | 16 | 76.9(73.8) | 7.7 | 12.5 | - | 41 | 57 | - | 29 | 32 | - |

| 80 | 3 | 16 | 89.8 | 8.3 | 13.8 | - | 57 | 64 | - | 32 | 35 | - |

| 100 | 4 | 19 | 115.5 | 9.4 | - | - | 66 | - | - | 42 | - | - |

Socket weld & Threaded Tee

| Nominal Diameter |

Depth of Socket |

Dimension of Socket |

Wall Thickness | Center to bottom of socket | |||||

|---|---|---|---|---|---|---|---|---|---|

| A | |||||||||

| Cmin | Tee | ||||||||

| DN | NPS (inches) |

Jmin | d1 | 3000LB | 6000LB | 9000LB | 3000LB | 6000LB | 9000LB |

| 6 | 1/8 | 10 | 10.7 | 3.2 | 3.5 | - | 11 | 11 | - |

| 8 | 1/4 | 10 | 14.1 | 3.3 | 4 | - | 11 | 15 | - |

| 10 | 3/8 | 10 | 17.5 | 3.5 | 4.4 | - | 13 | 15 | - |

| 15 | 1/2 | 10 | 21.8 | 4.1 | 5.2 | 8.2 | 16 | 19 | 25 |

| 20 | 3/4 | 13 | 27.4 | 4.3 | 6.1 | 8.6 | 19 | 22 | 28 |

| 25 | 1 | 13 | 34.2 | 5 | 7 | 10 | 22 | 27 | 32 |

| 32 | 1.1/4 | 13 | 42.9 | 5.3 | 7 | 10.6 | 27 | 32 | 35 |

| 40 | 1.1/2 | 13 | 48.3 | 5.6 | 7.8 | 11.2 | 32 | 38 | 38 |

| 50 | 2 | 13 | 61.1 | 6.1 | 9.5 | 12.2 | 38 | 41 | 41 |

| 65 | 2.1/2 | 16 | 76.9(73.8) | 7.7 | 12.5 | - | 41 | 57 | - |

| 80 | 3 | 16 | 89.8 | 8.3 | 13.8 | - | 57 | 64 | - |

| 100 | 4 | 19 | 115.5 | 9.4 | - | - | 66 | - | - |

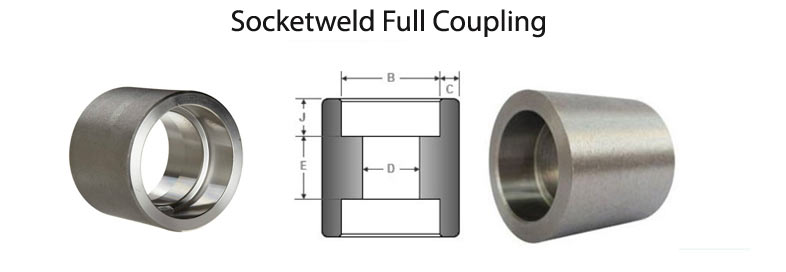

| Nominal Diameter |

Depth of Socket |

Dimension of Socket |

Wall Thickness | End Wall Thickness | The Lenth of Midst | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cmin | Kmin | Coupling | Half-Coupling | |||||||||

| DN |

NPS (inches) |

Jmin | d1 | 3000LB | 6000LB | 9000LB | 3000LB | 6000LB | 9000LB | E | F | |

| 6 | 1/8 | 10 | 10.7 | 3.2 | 3.5 | - | 5 | 6.5 | - | 6 | 16 | |

| 8 | 1/4 | 10 | 14.1 | 3.3 | 4 | - | 5 | 6.5 | - | 6 | 16 | |

| 10 | 3/8 | 10 | 17.5 | 3.5 | 4.4 | - | 5 | 6.5 | - | 6 | 17 | |

| 15 | 1/2 | 10 | 21.8 | 4.1 | 5.2 | 8.2 | 6.5 | 8 | 11 | 10 | 22 | |

| 20 | 3/4 | 13 | 27.4 | 4.3 | 6.1 | 8.6 | 6.5 | 8 | 12.5 | 10 | 24 | |

| 25 | 1 | 13 | 34.2 | 5 | 7 | 10 | 9.5 | 11 | 14 | 13 | 29 | |

| 32 | 1.1/4 | 13 | 42.9 | 5.3 | 7 | 10.6 | 9.5 | 11 | 14 | 13 | 30 | |

| 40 | 1.1/2 | 13 | 48.3 | 5.6 | 7.8 | 11.2 | 11 | 12.5 | 16 | 13 | 32 | |

| 50 | 2 | 13 | 61.1 | 6.1 | 9.5 | 12.2 | 12.5 | 16 | 19 | 19 | 41 | |

| 65 | 2.1/2 | 16 | 76.9(73.8) | 7.7 | 12.5 | - | 16 | 19 | - | 19 | 43 | |

| 80 | 3 | 16 | 89.8 | 8.3 | 13.8 | - | 19 | 22 | - | 19 | 45 | |

| 100 | 4 | 19 | 115.5 | 9.4 | - | - | 22 | 28.5 | - | 19 | 48 | |

| 1/8" to 4" class 3000 & 6000 threaded | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Class 3000 |

Inches | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 3/4 | 3/4 | 7/8 | 1 1/8 | 1 3/8 | 1 3/4 | 2 1/4 | 2 1/2 | 3 | 3 5/8 | 4 1/4 | 5 1/2 | |

| D | 15/16 | 1 | 1 | 1 1/4 | 1 7/16 | 1 5/8 | 1 3/4 | 1 3/4 | 1 7/8 | 2 3/8 | 2 9/16 | 2 11/16 | |

| Class 6000 | Inches | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 7/8 | 1 | 1 1/4 | 1 1/2 | 1 3/4 | 2 1/4 | 2 1/2 | 3 | 3 5/8 | 4 1/4 | 5 | 6 1/4 | |

| D | 1 | 1 1/16 | 1 | 1 5/16 | 1 1/2 | 1 11/16 | 1 13/16 | 1 7/8 | 2 | 2 1/2 | 2 11/16 | ||

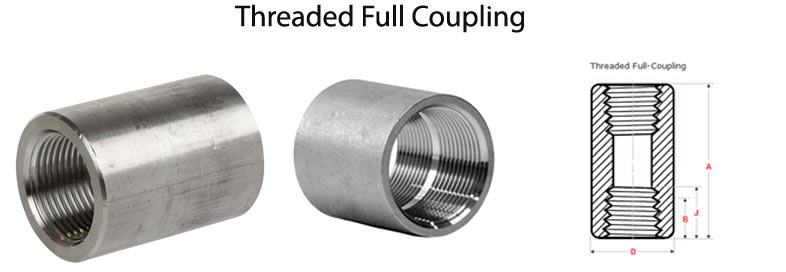

| Nominal Diameter |

Depth of Socket |

Dimension of Socket |

Wall Thickness | End Wall Thickness | The Lenth of Midst | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cmin | Kmin | Coupling | Half-Coupling | |||||||||

| DN |

NPS (inches) |

Jmin | d1 | 3000LB | 6000LB | 9000LB | 3000LB | 6000LB | 9000LB | E | F | |

| 6 | 1/8 | 10 | 10.7 | 3.2 | 3.5 | - | 5 | 6.5 | - | 6 | 16 | |

| 8 | 1/4 | 10 | 14.1 | 3.3 | 4 | - | 5 | 6.5 | - | 6 | 16 | |

| 10 | 3/8 | 10 | 17.5 | 3.5 | 4.4 | - | 5 | 6.5 | - | 6 | 17 | |

| 15 | 1/2 | 10 | 21.8 | 4.1 | 5.2 | 8.2 | 6.5 | 8 | 11 | 10 | 22 | |

| 20 | 3/4 | 13 | 27.4 | 4.3 | 6.1 | 8.6 | 6.5 | 8 | 12.5 | 10 | 24 | |

| 25 | 1 | 13 | 34.2 | 5 | 7 | 10 | 9.5 | 11 | 14 | 13 | 29 | |

| 32 | 1.1/4 | 13 | 42.9 | 5.3 | 7 | 10.6 | 9.5 | 11 | 14 | 13 | 30 | |

| 40 | 1.1/2 | 13 | 48.3 | 5.6 | 7.8 | 11.2 | 11 | 12.5 | 16 | 13 | 32 | |

| 50 | 2 | 13 | 61.1 | 6.1 | 9.5 | 12.2 | 12.5 | 16 | 19 | 19 | 41 | |

| 65 | 2.1/2 | 16 | 76.9(73.8) | 7.7 | 12.5 | - | 16 | 19 | - | 19 | 43 | |

| 80 | 3 | 16 | 89.8 | 8.3 | 13.8 | - | 19 | 22 | - | 19 | 45 | |

| 100 | 4 | 19 | 115.5 | 9.4 | - | - | 22 | 28.5 | - | 19 | 48 | |

| 1/8" to 4" class 3000 & 6000 threaded | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Class 3000 |

Inches | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 3/4 | 3/4 | 7/8 | 1 1/8 | 1 3/8 | 1 3/4 | 2 1/4 | 2 1/2 | 3 | 3 5/8 | 4 1/4 | 5 1/2 | |

| D | 15/16 | 1 | 1 | 1 1/4 | 1 7/16 | 1 5/8 | 1 3/4 | 1 3/4 | 1 7/8 | 2 3/8 | 2 9/16 | 2 11/16 | |

| Class 6000 | Inches | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 7/8 | 1 | 1 1/4 | 1 1/2 | 1 3/4 | 2 1/4 | 2 1/2 | 3 | 3 5/8 | 4 1/4 | 5 | 6 1/4 | |

| D | 1 | 1 1/16 | 1 | 1 5/16 | 1 1/2 | 1 11/16 | 1 13/16 | 1 7/8 | 2 | 2 1/2 | 2 11/16 | 2 15/16 | |

| Nominal Diameter |

Outside Diameter | Wall Thickness |

Socket Bore |

Water way Bore |

Depth of Socket |

Length Assem Nominal |

|||

|---|---|---|---|---|---|---|---|---|---|

| Dmin | Cmin | d1 | d2 | Jmin | L | ||||

| DN |

NPS (inches) |

Socket | Threaded | Socket | Threaded | Socket |

Socket & Threaded |

Socket |

Socket & Threaded |

| 6 | 1/8 | 21.8 | 14.7 | 3.2 | 2.5 | 10.65 | 6.43 | 10 | 41.4 |

| 8 | 1/4 | 21.8 | 19 | 3.3 | 3.1 | 14.1 | 9.45 | 10 | 41.4 |

| 10 | 3/8 | 25.9 | 22.9 | 3.5 | 3.2 | 17.55 | 13.51 | 10 | 46 |

| 15 | 1/2 | 31.2 | 27.7 | 4.1 | 3.8 | 21.7 | 17.07 | 10 | 49 |

| 20 | 3/4 | 37.1 | 33.5 | 4.3 | 4 | 27.05 | 21.39 | 13 | 56.9 |

| 25 | 1 | 45.5 | 41.4 | 5 | 4.6 | 33.8 | 27.74 | 13 | 62 |

| 32 | 11/4 | 54.9 | 50.5 | 5.3 | 4.9 | 42.55 | 35.36 | 13 | 71.1 |

| 40 | 11/2 | 61.5 | 57.2 | 5.6 | 5.1 | 48.65 | 41.2 | 13 | 76.5 |

| 50 | 2 | 75.2 | 70.1 | 6.1 | 5.6 | 61.1 | 52.12 | 16 | 86.1 |

| 65 | 21/2 | 91.7 | 85.3 | 7.7 | 7.1 | 73.8 | 64.31 | 16 | 102.4 |

| 80 | 3 | 109.2 | 102.4 | 8.4 | 7.7 | 89.8 | 77.27 | 16 | 109 |

| 1/8" to 3" class 3000 & 1/2" to 2" class 6000 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Class 3000 |

Inches | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 |

| A | 1 11/16 | 1 11/16 | 1 27/32 | 2 | 2 5/16 | 2 7/16 | 2 7/8 | 3 | 3 1/2 | 4 1/2 | 4 7/16 | |

| B | 1 31/64 | 1 31/64 | 1 11/16 | 1 15/16 | 2 3/8 | 2 25/32 | 3 23/64 | 3 23/32 | 4 27/64 | 5 15/64 | 6 5/32 | |

| C | 53/64 | 53/64 | 1 | 1 3/16 | 1 15/32 | 1 25/32 | 2 7/32 | 2 35/64 | 3 1/16 | 3 9/16 | 4 9/32 | |

| D | 25/32 | 25/32 | 31/32 | 1 3/32 | 1 5/32 | 1 3/8 | 1 45/64 | 1 7/8 | 2 1/16 | 2 3/8 | 2 7/16 | |

| E | 7/16 | 7/16 | 7/16 | 7/16 | 9/16 | 9/16 | 9/16 | 9/16 | 11/16 | 7/8 | 1 | |

| F | 0.42 | 0.555 | 0.69 | 0.855 | 1.065 | 1.33 | 1.675 | 1.915 | 2.406 | 2.906 | 3.535 | |

| 0.43 | 0.565 | 0.7 | 0.865 | 1.075 | 1.34 | 1.685 | 1.925 | 2.416 | 2.921 | 3.55 | ||

| Class 6000 | Inches | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | ||

| A | 1 11/15 | 1 27/32 | 2 | 2 5/16 | 2 7/16 | 2 7/8 | 3 | 3 1/2 | 4 1/8 | |||

| B | 1 31/64 | 1 11/16 | 1 15/16 | 2 3/8 | 2 25/32 | 3 23/64 | 3 23/32 | 4 27/64 | 5 15/64 | |||

| C | 53/64 | 1 | 1 3/16 | 1 15/32 | 1 25/32 | 2 7/32 | 2 35/64 | 3 1/16 | 3 9/16 | |||

| D | 25/32 | 31/32 | 1 3/32 | 1 5/32 | 1 3/8 | 1 45/64 | 1 7/8 | 2 1/16 | 2 3/8 | |||

| E | 7/16 | 7/16 | 7/16 | 9/16 | 9/16 | 9/16 | 9/16 | 11/16 | 7/8 | |||

| F | 0.42 | 0.555 | 0.69 | 0.855 | 1.065 | 1.33 | 1.675 | 1.915 | 2.406 | |||

| 0.43 | 0.565 | 0.7 | 0.865 | 1.075 | 1.34 | 1.685 | 1.925 | 2.416 | ||||

| Nominal Diameter |

Depth of Socket |

Dimension of Socket |

Wall Thickness | End Wall Thickness | |||||

|---|---|---|---|---|---|---|---|---|---|

| Cmin | Kmin | ||||||||

| DN | NPS (inches) |

Jmin | d1 | 3000LB | 6000LB | 9000LB | 3000LB | 6000LB | 9000LB |

| 6 | 1/8 | 10 | 10.7 | 3.2 | 3.5 | - | 5 | 6.5 | - |

| 8 | 1/4 | 10 | 14.1 | 3.3 | 4 | - | 5 | 6.5 | - |

| 10 | 3/8 | 10 | 17.5 | 3.5 | 4.4 | - | 5 | 6.5 | - |

| 15 | 1/2 | 10 | 21.8 | 4.1 | 5.2 | 8.2 | 6.5 | 8 | 11 |

| 20 | 3/4 | 13 | 27.4 | 4.3 | 6.1 | 8.6 | 6.5 | 8 | 12.5 |

| 25 | 1 | 13 | 34.2 | 5 | 7 | 10 | 9.5 | 11 | 14 |

| 32 | 1.1/4 | 13 | 42.9 | 5.3 | 7 | 10.6 | 9.5 | 11 | 14 |

| 40 | 1.1/2 | 13 | 48.3 | 5.6 | 7.8 | 11.2 | 11 | 12.5 | 16 |

| 50 | 2 | 13 | 61.1 | 6.1 | 9.5 | 12.2 | 12.5 | 16 | 19 |

| 65 | 2.1/2 | 16 | 76.9(73.8) | 7.7 | 12.5 | - | 16 | 19 | - |

| 80 | 3 | 16 | 89.8 | 8.3 | 13.8 | - | 19 | 22 | - |

| 100 | 4 | 19 | 115.5 | 9.4 | - | - | 22 | 28.5 | - |

| 1/8" to 4" class 3000 & 6000 threaded | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Class 3000 |

Inches | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 3/4 | 3/4 | 7/8 | 1 1/8 | 1 3/8 | 1 3/4 | 2 1/4 | 2 1/2 | 3 | 3 5/8 | 4 1/4 | 5 1/2 | |

| D | 15/16 | 1 | 1 | 1 1/4 | 1 7/16 | 1 5/8 | 1 3/4 | 1 3/4 | 1 7/8 | 2 3/8 | 2 9/16 | 2 11/16 | |

| Class 6000 | Inches | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 7/8 | 1 | 1 1/4 | 1 1/2 | 1 3/4 | 2 1/4 | 2 1/2 | 3 | 3 5/8 | 4 1/4 | 5 | 6 1/4 | |

| D | 1 | 1 1/16 | 1 | 1 5/16 | 1 1/2 | 1 11/16 | 1 13/16 | 1 7/8 | 2 | 2 1/2 | 2 11/16 | 2 15/16 | |